- TJ

- shanghai,china

- 10-15days

- 30 units per month

The 4 Sides Seal Granule Powder Liquid Packing Machine adds detailed functions such as opening and stopping, exhausting, compaction, automatic carding, abnormal discharge, automatic filling of lubricating oil, etc. The whole process of packaging does not require manual work, which effectively improves production efficiency and saves labor costs. And management costs, significantly reducing costs and increasing production efficiency.

4 Sides Seal Granule Powder Liquid Packing Machine

4 Sides Seal Granule Powder Liquid Packing Machine fault description

1. The length of the bag does not match the set value.

2, the length of the bag is inconsistent.

3, the error in the light eye tracking is large.

4, the film stepper motor does not work.

5, the 4 Sides Seal Granule Powder Liquid Packing Machine packs dozens of bags or hundreds of bags each time, a few packets are not normal.

6, the screw is not working properly, the stepper motor has a lost sound.

7, the screw does not run, the stepper motor does not move.

8. The 4 Sides Seal Granule Powder Liquid Packing Machine automatically stops and displays the "Proximity Switch".

9. After pressing the start button, the 4 Sides Seal Granule Powder Liquid Packing Machine does not move and the computer displays "Proximity Switch".

10, after starting the host, press the "Start / Stop" button, the host can not stop If the above fault occurs, please contact the technician.

4 Sides Seal Granule Powder Liquid Packing Machine Technical Parameters

Model | TJ-150J |

Packing range | 5-100ml |

Packing speed | 30-60 bags/min |

Making bag size | L50-150mm, W15-130mm |

Packing accuracy | ≤±1% |

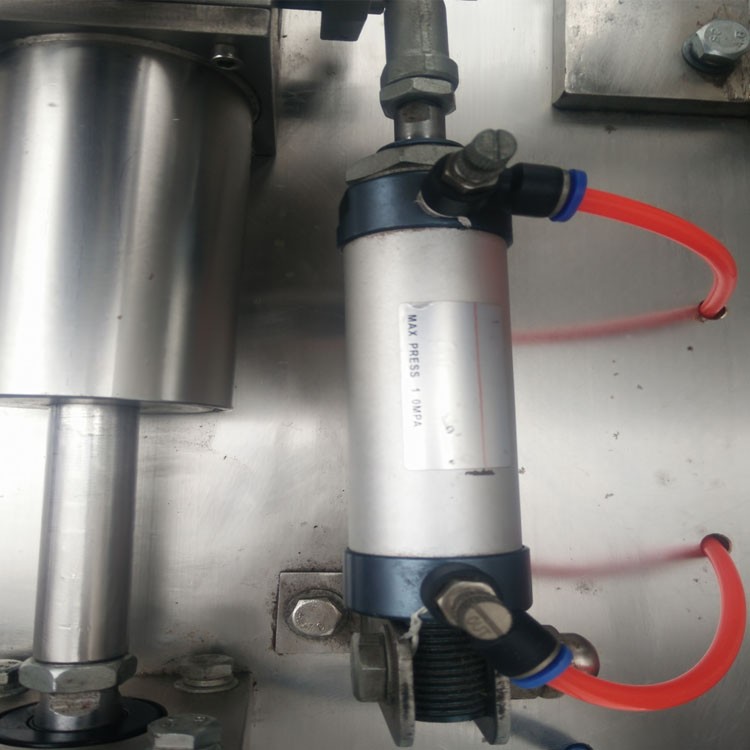

Air Consumption | 0.8Mpa,0.3m³/min |

Power | 1.6 KW |

Seal Type | 3/4 sides seal,pillow seal |

Power supply | 1 Ph,AC220V, 50/60Hz |

Net Weight | 250kg |

Machine dimension | L800*W680*H1800mm |

4 Sides Seal Granule Powder Liquid Packing Machine features

1. The 4 Sides Seal Granule Powder Liquid Packing Machine adds detailed functions such as opening and stopping, exhausting, compaction, automatic carding, abnormal discharge, automatic filling of lubricating oil, etc. The whole process of packaging does not require manual work, which effectively improves production efficiency and saves labor costs. And management costs, significantly reducing costs and increasing production efficiency.

2. The parts in contact with the packaging bag and materials are processed by stainless steel or other materials that meet the requirements of food hygiene to ensure the hygiene and safety of the food and meet the food hygiene standards.

3. The 4 Sides Seal Granule Powder Liquid Packing Machine adopts the latest German PLC control system. The inverter is steplessly variable, and the main motor, PLC, inverter, sensor, relay, contactor and pneumatic components are all international famous brands.machine.