- TJ

- shanghai,china

- 10-15days

- 30 units per month

This Automatic Honey Pouch Packing Machine automatically completes a series of processes such as bag making, metering, blanking, sealing, slitting and counting.

Automatic Honey Pouch Packing Machine

Automatic Honey Pouch Packing Machine introduction

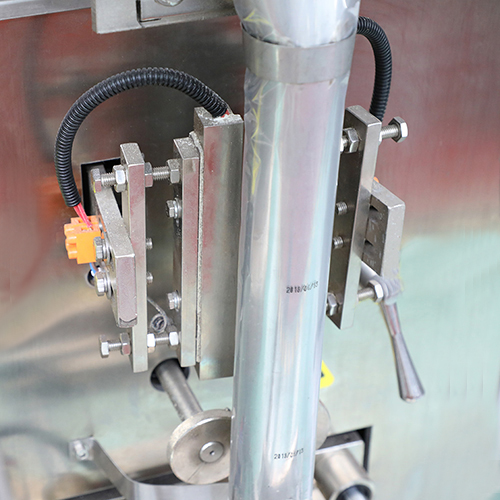

1. All parts in contact with the packaged materials are made of SU304 stainless steel or non-toxic materials. The exterior of the machine is made of stainless steel sealing structure, which meets the QS and GMP hygiene requirements.

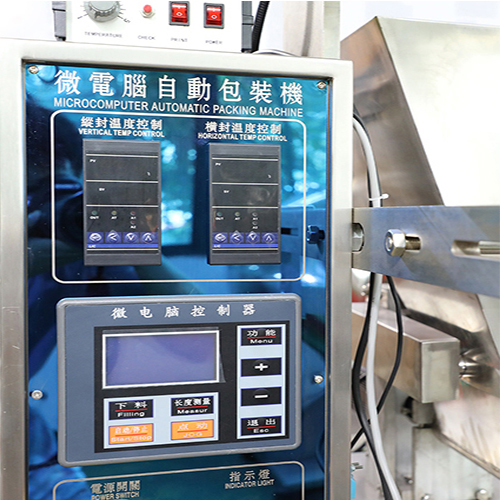

2. The controller of the Automatic Honey Pouch Packing Machine adopts the computer screen control panel, the Chinese and English display interface is intuitive and clear, the parameter adjustment is convenient and fast, and the fault self-display function is provided to help solve the fault in time.

3. The metering method can adopt mechanical/pneumatic piston pump, screw pump, self-priming pump, etc., for automatic metering and cutting.

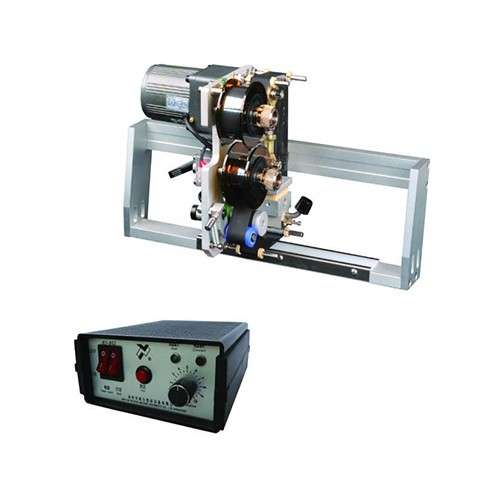

4. According to customer requirements, you can choose to configure the coding machine, self-adhesive labeling machine, thermal transfer, nitrogen filling device, exhaust device, easy tearing, hanging holes, etc.

5. This Automatic Honey Pouch Packing Machine hopper uses automatic electric heater to keep the material at a constant temperature and has fluidity.

Automatic Honey Pouch Packing Machine Technical Parameters

Model | TJ-280J |

Packing range | 10-350ml |

Packing speed | 30-50 bags/min |

Making bag size | L50-280mm, W15-130mm |

Packing accuracy | ≤±1% |

Air Consumption | 0.8Mpa,0.3m³/min |

Power | 1.6 KW |

Seal Type | 3/4 sides seal,pillow seal |

Power supply | 1 Ph,AC220V, 50/60Hz |

Net Weight | 300kg |

Machine dimension | L800*W680*H1950mm |

Automatic Honey Pouch Packing Machine product features

1. This Automatic Honey Pouch Packing Machine automatically completes a series of processes such as bag making, metering, blanking, sealing, slitting and counting.

2. The bag making system of the Automatic Honey Pouch Packing Machine adopts advanced motor control, photoelectric eye color mark positioning and tracking, beautiful bag making and stable performance.

3.PID independent temperature regulation control, four-way heating control of heat sealer, each side of the closed circuit can be separately tempered; good heat balance, high sealing quality, suitable for a variety of packaging materials.