- TJ

- shanghai,china

- 15-30days

- 30 units per month

The High Speed Rotary Tablet Press has some functions, such as frequency control, filling and thickness of tablet display, average pressure display, overload protection, emergency braking and so on .

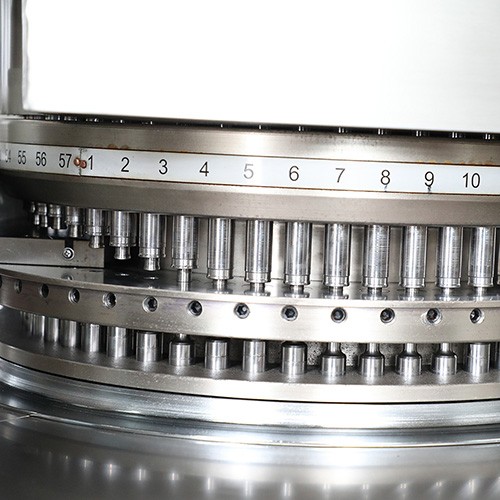

High Speed Rotary Tablet Press

High Speed Rotary Tablet Press Main features

Mechanical parts of the High Speed Rotary Tablet Press: key parts of the material (material):

Copper rail material adopted specially formulated casting a military enterprise, improve the wear resistance.

The top cap, turntable, rail, track plate, main body and so on, adopts unique technology of casting by a sole proprietorship enterprise of Japan. By analyzing metallographic experiment, uniform material internal molecular structure of the body, tight, no bubble, trachoma and crack, inner pressure and reliable, the casting surface level off, smooth. Main shaft adopts special mark of forgings, small deformation and good rigidity.

Processing technology of parts of the High Speed Rotary Tablet Press:

Copper track, on the roof, turntable, rail, rail bridge, the main body and other major parts adopt precision machine tools (machining center), the processing dimensional accuracy is high.

Improvement of the pressure roller and wheel frame structure of the High Speed Rotary Tablet Press:

Native roller frame structure change of the current tablet press is widely used form of leveraged (or pole type), using column type structure, its advantage is pressure point, pressure big, less noise and small volume etc.

High Speed Rotary Tablet Press Technical Parameters

Model | HSZP-35 | HSZP-37 | HSZP-43 | HSZP-45 | HSZP-53 | HSZP-57 | |

No.of Stations | 35 | 37 | 43 | 45 | 53 | 57 | |

Type of Tooling | IPT | IPT | IPT | IPT | IPT | IPT | |

Max. Pressure (kn) | 80 | 80 | 80 | 80 | 80 | 80 | |

Max. Pre-pressure (kn) | 60 | 60 | 60 | 60 | 60 | 60 | |

Max. Filling Depth (mm) | 18 | 18 | 18 | 18 | 18 | 18 | |

Max. Tablet Dia (mm) | 25 | 23 | 18 | 17 | 13 | 11 | |

Max. Tablets output (ten thousand/ hour) | 18.9 | 19.98 | 23.22 | 24.3 | 28.62 | 30.78 | |

Max. Turret Speed (r/min) | 45 | 45 | 45 | 45 | 45 | 45 | |

Main Motor Power(kw) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | |

Height of the Machine (mm) | Without Hopper | 1750 | 1750 | 1750 | 1750 | 1750 | 1750 |

With Hopper | 1900 | 1900 | 1900 | 1900 | 1900 | 1900 | |

Machine Floor Space (mm²) | 1170*1290 | 1170*1290 | 1170*1290 | 1170*1290 | 1170*1290 | 1170*1290 | |

Machine Net Weight(kg) | 3500 | 3500 | 3500 | 3500 | 3500 | 3500 | |

High Speed Rotary Tablet Press Introduction

1. Mechanical and electrical components of the machine configuration is excellent, mechanical components using high strength and high rack mechanism stiffness of frame body, the main casting adopt Japanese-owned company’s products, special processing technology turntable structure, the main pressure preload wheel and wheel structure lubrication system uses American-owned Beiqier company's products, the main motor is ABB's products, inverters, displays adopts Siemens products.

2. Fully enclosed work area uses transparent window structure, less dust pollution, excellent sealing.

3. The working chamber of the High Speed Rotary Tablet Press is completely separated from the transmission mechanism, prevent cross-infection effectively. Parts in contact with the medicine are made of stainless steel or with special surface treatment, no dead corner in working room, loading and unloading easily, easy cleaning and maintenance, compliance with medicine production and quality management practices of GMP standards.

4. The High Speed Rotary Tablet Press has some functions, such as frequency control, filling and thickness of tablet display, average pressure display, overload protection, emergency braking and so on