- TJ

- shanghai,china

- 10-15days

- 30 units per month

Multifunctional Bottle Label Machine production line is divided into low speed line, medium speed line and high speed line. Here is the JF-2000-32 Grain counting bottling packaging linkage production line.

RXL-A Vertical Round Bottle Labeling Machine Introduction

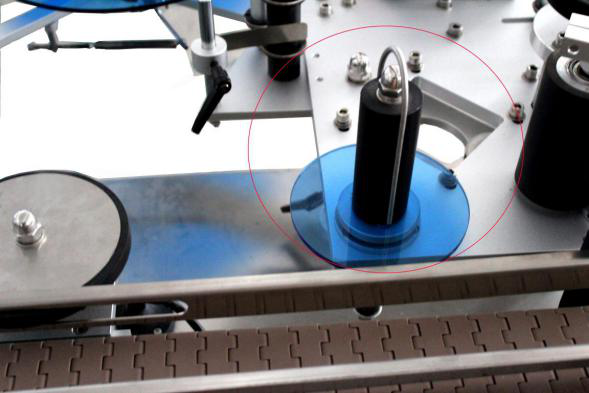

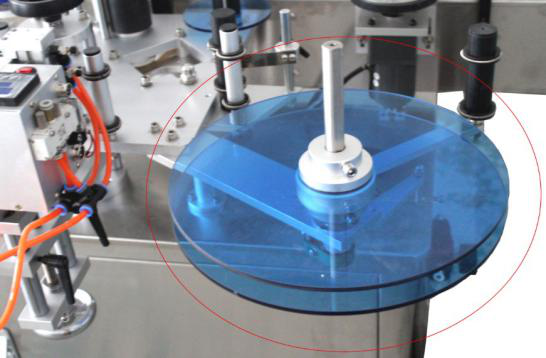

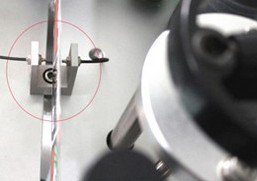

1.Machine image:

2.Related introduction:

The RXL-A vertical round bottle sticker labeler is designed to achieve a rationalized production goal. The labeling process is automated, the operation is simple, the production speed is fast, the labeling position is uniform, beautiful, and tidy; it is suitable for the round container labeling in the pharmaceutical, chemical, food and other industries, and can be labeled on the whole circle and half circumference. Optional ribbon coder and printer, labeling at the same time to achieve print production batch number, production date and other information. To achieve the integration of labeling and coding, reduce packaging processes and increase production efficiency.

3.Work flow:

manually put the product to be posted (connected or bottle feeder) →automatic product correction and delivery→ product testing → product labeling→ collection of labeled products (go to the next process) → Take away the product.

4.Working principle:

After the bottle enters the labeling machine conveyor belt, it is fed to the labeling machine at a constant speed. The mechanical fixing device is separated by a fixed distance between the stickers and pushes the attached object along the direction of the conveyor belt. . After the mechanical system (driving wheel, labeling wheel, reel) driving wheel intermittently dragging the label tape movement, the label is pulled out from the reel and pasted on the attached object by the labeling device.

5.Equipment advantages:

(1) Simple adjustment, configuration before and after, left and right and up and down direction, plane inclination angle, vertical plane inclination angle adjustment seat, no dead angle of different bottle shape switching, in line with GMP production requirements;

(2) Automatically divide the bottle, effectively eliminate the error caused by the bottle itself is not smooth, and improve stability;

(3) With automatic stop function, production count function, power saving function (the device automatically goes to power saving standby state when there is no production within the set time), production number setting prompt function, parameter setting protection function (parameter setting sub-rights management), Convenient production management;

(4) Powerful, color touch screen control, Chinese and English optional operation interface, convenient and intuitive, powerful data memory function, can store 50 sets of labeling parameters, with production count function, power saving function, production number setting prompt function, parameter setting protection function , Convenient for production management, one-button switching of different product labeling, no need for repeated debugging, simple and quick, and with perfect fault indication and help function;

(5) High stability, the use of imported brands for measuring and testing sensors, high detection sensitivity, stable performance, and durability; stable and durable bases and various parts, all adopting standardized modular design with complete interchangeability, 24 Hours of operation to ensure safety and stability.

(6)Safety and health, chassis, stainless steel SUS304 material and T6 aluminum alloy, never rust, in line with GMP excellent manufacturing standards;

6.Optional features and components:

(1) Coder: The thermal coder prints the production date, expiration date, and production lot number. Synchronizing coding and labeling to increase production efficiency.

(2) Inkjet printer:It can be used to match the mainstream inkjet printers on the market, and conducts coding at the designated position of the label, which is in perfect combination with the labeling machine.

(3) Universal sensor: ordinary sensors can not detect the transparent label, must use the German import Leuze special electric eye supporting use. The

(4)Reader: Reads information such as QR codes and bar codes to facilitate the establishment of a product database for product traceability.

7.Technical Parameter:

Voltage specification | AC220V 50/60HZ |

Power consumption | 980W |

Labeling speed | 200-400b/m (Adjustable speed, depending on bottle size and label length) |

Labeling accuracy | +1mm(Depends on product characteristics, hardness and trueness of the circle) |

Bottle diameter | 25-120mm |

Object range | Height:20mm~~300mm(Can be customized according to customer requirements) |

Label specifications | Height:10mm~~150mm Length: 15~~300mm (Special specifications can be customized) |

Roll diameter | Φ76mm Outer roll diameter:Φ300(max) |

Weight | 200KG |

Package Size | 1950*1100*1300mm |

Conveyor belt width | Can be customized according to customer's sample bottle diameter |

8.Configuration list:

Number | Name | Quantity | Brand | place of origin |

1 | Human-machine interface HIM | 1 | Delta | Taiwan |

2 | Programmable controller PLC | 1 | Delta | Taiwan |

3 | Labeling motor | 1 | Stepping | China |

4 | Labeling motor driver | 1 | Stepping | China |

5 | Conveyor motor | 1 | Jianming | China |

6 | Conveyor motor frequency converter | 1 | Delta | Germany |

7 | sub-bottle motor | 1 | JSCC | Germany |

8 | sub-bottle motor controller | 1 | JSCC | Germany |

9 | Label motor | 1 | JSCC | Germany |

10 | Label motor controller | 1 | JSCC | Germany |

11 | Low-voltage electrical appliances | 1 | Schneider | France |

12 | Label sensor | 1 | Omron | Japan |

13 | Labeling sensor | 1 | Omron | Japan |

14 | Synchronous toothed belt | 1 | Osaka | Japan |

15 | Pneumatic originals | 1 | AirTAC | Taiwan |

16 | Belt | 1 | Lilai | China |

17 | frame | 1 | 304 stainless steel | China |

18 | system integration | 1 | self made | China |

9. Main components performance characteristics

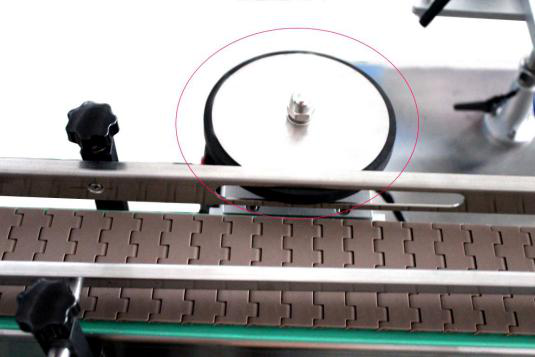

(1) Sub-bottle correction mechanism:Motor control automatically adjusts the bottle distance and direction to ensure consistency.

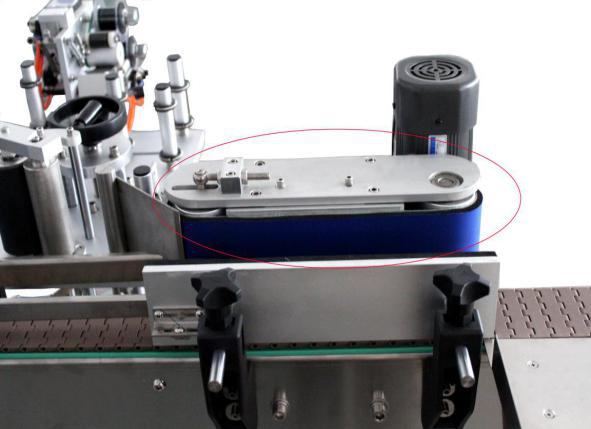

(2) Labeling power mechanism:The use of servo motor as the power, with the eccentric mechanism to press the label paper for power scrolling, using the stripping plate at the same time when rolling.

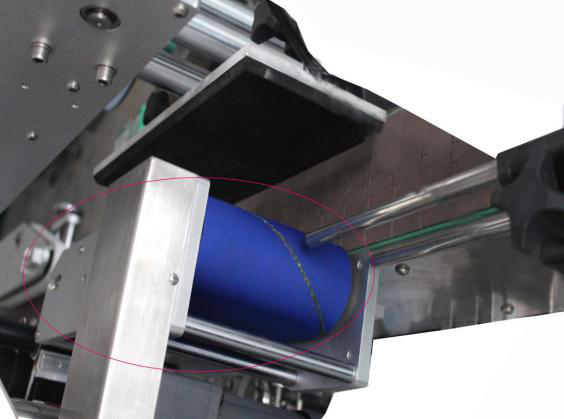

(3) Pulling agency: The synchronization of motor control and conveyor ,output label .

(4) Receiving agency: The motor control synchronizes with the conveyor belt and the labeling mechanism to collect the label backing paper.

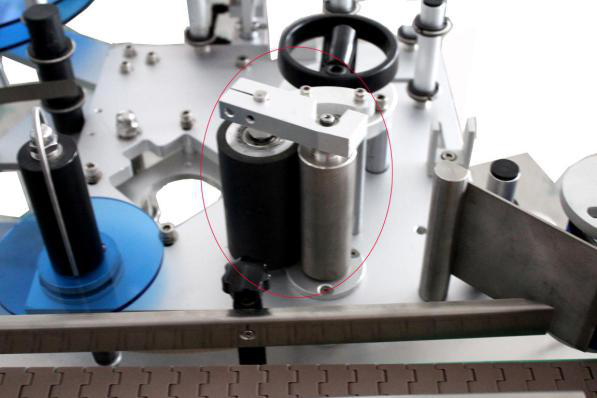

(5) Label roller device: Nice, dustproof, easy to change labels.

(6) Removing label system : you can adjust the label to remove the location, label removal and the location of the label to quickly fine-tune, change the standard and convenient.

(7) Photoelectric detection: One-to-one correspondence between the control bottle and the label, no bottle no label, no duplicate label.

(8) PLC man-machine touch control screen:Simple, convenient and easy to learn.

(9) Conveyor chain:Imported brands, easy to clean and durable.

(10) Alarm system:Sound and light alarm device, more convenient production supervision, emergency stop button, the maximum protection of personnel safety.