- TJ

- Shanghai,China

- 15-30days

- 30 units per month

The mechanical buffer on the Rotary Tablet Press Machine With D Tooling prevents damage to the machine due to overload. There is a suction box inside the machine. The nozzle can absorb the dust generated when the machine is rotated, avoiding the adhesive blockage, and recycling the raw materials for reuse.

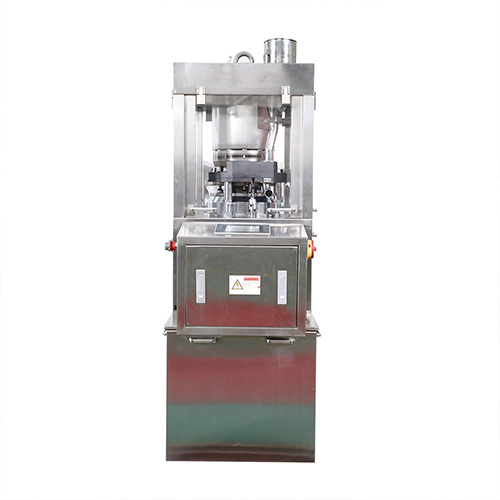

Rotary Tablet Press Machine With D Tooling

Rotary Tablet Press Machine With D Tooling Characteristics

1. All the controller and devices are located in one side of the machine, so that Rotary Tablet Press Machine With D Tooling can be easier to operate

2. An overload protection unit is included in the system to avoid the damage of the punches and apparatus, when overload occurs.

3. The machine's worm gear drive adopts fully-enclosed oil-immersed lubrication, so Rotary Tablet Press Machine With D Tooling has a long service life, preventing cross pollution.

Rotary Tablet Press Machine With D Tooling Technique Parameter

Model | ZPS-8 | ZPS-10 | ZPS-18 |

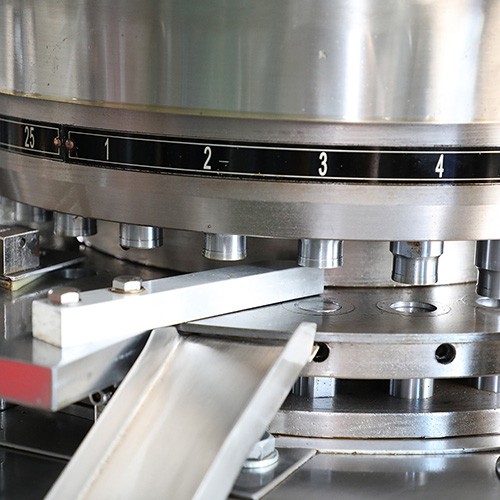

Dies (sets) | 8 | 10 | 18 |

Type of Tooling | 1′D | 1′D | 1′D |

Max. Pressure (kn) | 80 | 80 | 60 |

Max. Pre-Pressure(kn) | 10 | 10 | 10 |

Max. Tablet Diameter (mm) | 22 | 22 | 16 |

Max. Filling Depth (mm) | 17 | 17 | 17 |

Max. Thickness of largest tablet (mm) | 6 | 6 | 6 |

Max. Turret Speed(r/min) | 5-30 | 5-30 | 5-30 |

Capacity (pcs/hour) | 14400 | 18000 | 32000 |

Motor Power (kw) | 2.2 | 2.2 | 2.2 |

Overall dimensions (mm) | 750×660×1620 | ||

Net weigh t(kg) | 780 | ||

Rotary Tablet Press Machine With D Tooling Operation: The operation of theRotary Tablet Press Machine With D Tooling is no different from that of a general-purpose computer. This is very low for the operator and can be easily learned by a computer or mobile phone .

When the Rotary Tablet Press Machine With D Tooling press performs the tableting, the speed of the turntable, the filling depth of the material, and the thickness of the tablet can be adjusted.

The mechanical buffer on the Rotary Tablet Press Machine With D Tooling prevents damage to the machine due to overload. There is a suction box inside the machine. The nozzle can absorb the dust generated when the machine is rotated, avoiding the adhesive blockage, and recycling the raw materials for reuse.