- TJ

- Shanghai,China

- 15-30days

- 30 units per month

The Rotary Tablet Press Machine For Pills Making is a lightweight, compact rotary tablet press. The whole machine is made of precision machining of stainless steel materials.

Rotary Tablet Press Machine For Pills Making

Rotary Tablet Press Machine For Pills Making operating skills

Before the Rotary Tablet Press Machine For Pills Making is working, the material must be screened for particles, so as to avoid the tablet loose pieces, splits, and wafer weight differences caused by the raw materials.

Selection of the type (mold): Correct selection of the type is an important step in the success of the tablet. For example, chewable tablets have higher hardness requirements and can be easily chewed, and most of them use a beveled flat sheet; a film coating can be selected as a shallow concave shape. In the case of the raw material, there is no binder or lubricant in the raw material, and the pressure is required to be large when the tablet is pressed, and the sheet type is preferably shallow. For tablets with a large sugar content, the sheet design is preferably shallow or flat. The medium mold can use alloy steel or hard alloy. The deep concave type die is easily damaged and is used as little as possible.

When removing the upper die of theRotary Tablet Press Machine For Pills Making, press the die with a clamp (to prevent damage caused by the forceps hitting the column, put a small piece of wood on the pliers), shake the handle with one hand, and hold the pliers with the other hand. , you can successfully remove the upper die.

When installing the upper die of the Rotary Tablet Press Machine For Pills Making, if you directly touch the middle die, the upper die may be operated. At this time, a piece of wood may be placed on the platen, and then the handle is shaken.

After using the Rotary Tablet Press Machine For Pills Making every day, remove the remaining particles and wipe off all parts of the machine. If the deactivation time is long, the die must be removed and the machine rubbed each side. Wipe the work surface, apply anti-rust oil, cover the dust-proof clothes; the die should be wiped clean and immersed in oil to save.

Rotary Tablet Press Machine For Pills Making Technique Parameter:

Technique parameter:

Model | ZPW-15D | ZPW-17D | ZPW-19D |

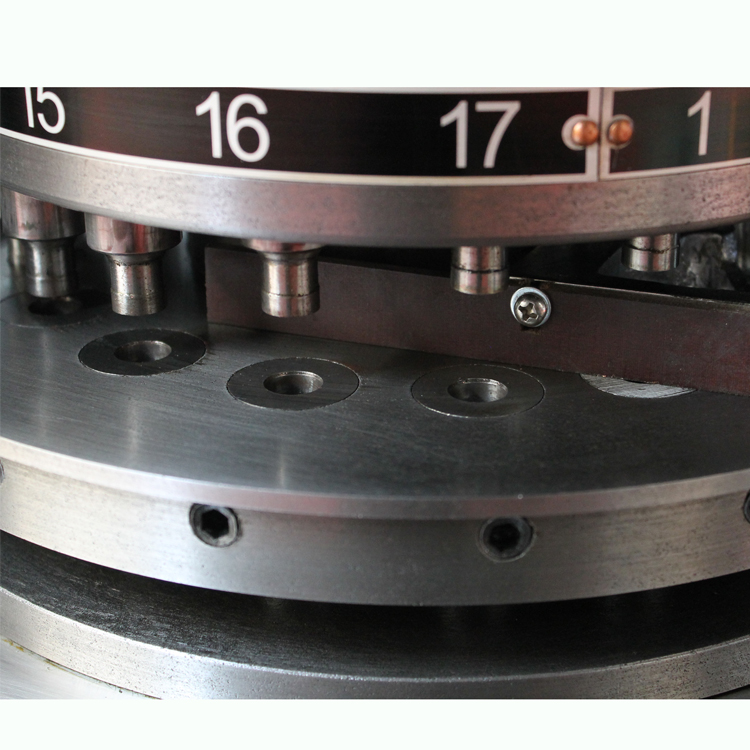

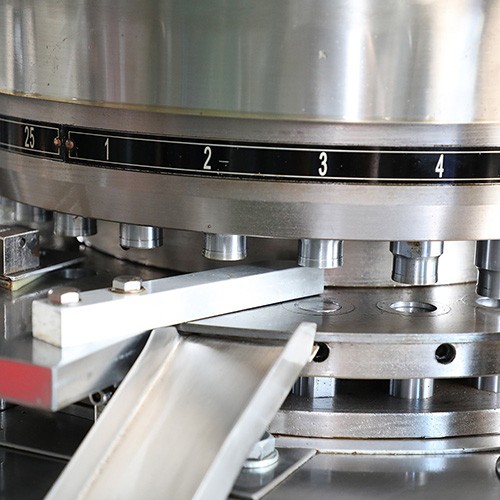

Dies (sets) | 15 | 17 | 19 |

Max. Pressure (kn) | 60 | 60 | 60 |

Max. dia. of tablet (mm) | 22 | 20 | 13 |

Max. Depth of fill (mm) | 15 | 15 | 15 |

Max. Thickness of largest table (mm) | 6 | 6 | 6 |

Production capacity (pcs/h) | 33000 | 40,000 | 42,000 |

Turret speed (r/min) | 37 | 37 | 37 |

Motor power (kw) | 2.2/960, 380V/50 | 2.2/960, 380V/50 | 2.2/960, 380V/50 |

Overall size (mm) | 615 x 890 x 1,415 | 615 x 890 x 1,415 | 615 x 890 x 1,415 |

Weight (kg) | 700 | 700 | 700 |

The Rotary Tablet Press Machine For Pills Making is a lightweight, compact rotary tablet press. The whole machine is made of precision machining of stainless steel materials.

The studio is sealed by a fully transparent plexiglass cover, which is effective against mosquitoes, dust, clean, beautiful, and the working conditions are clear at a glance. The waste is easy to clean and fully meets the national GMP production standards. The machine can press powder and small particles into round or shaped tablets of less than 12 mm, the output is 9,000-15,000 pieces / hour, the thickness of the tablet, the pressure and the tableting speed can be adjusted as required. The machine is suitable for use in the pharmaceutical, food, chemical, electronics and other industries. It is equipped with an overload protection device that automatically stops the Rotary Tablet Press Machine For Pills Makingwhen the pressure is overloaded.

The Rotary Tablet Press Machine For Pills Making is equipped with an electromagnetic brake motor and its other safety devices that can be adjusted and operated during operation.