- TJ

- shanghai,china

- 10-15days

- 30 units per month

Rotary Tablet Press With 9 Punches is a new generation product by our factory, and this machine is a single Roller continuous automatic tablet press for pressing various kinds of different shape tablets and plain tablets It is mainly used in pharmaceutical industry and also the chemical, food, electronic industries.

Rotary Tablet Press With 9 Punches

Rotary Tablet Press With 9 Punches construction instructions

1. Upper pressure roller frame device of Rotary Tablet Press With 9 Punches

The upper cover is a whole casting, and the pressure wheel is installed in the groove, which is sleeved on the crankshaft, and the outer shaft end has a mechanical rod connecting the coil spring. When the pressure surface is pressed too much, the eccentric moment of the crankshaft acts to compress the spring. The distance between the upper and lower pressure rollers reduces the pressure, so that the safety of the protection member and the die can be safely used. The pressure is adjusted, and the rotating flower-shaped handle changes the length of the spring so that the pressure of the spring is just enough.

2, the upper track device of the Rotary Tablet Press With 9 Punches

The guide rail is in the shape of a disc, and the heat-treated rail piece is embedded in the periphery, and is fastened by screws. The groove of the upper punching tail runs along the convex edge of the guide rail, and has a trajectory lifting movement.

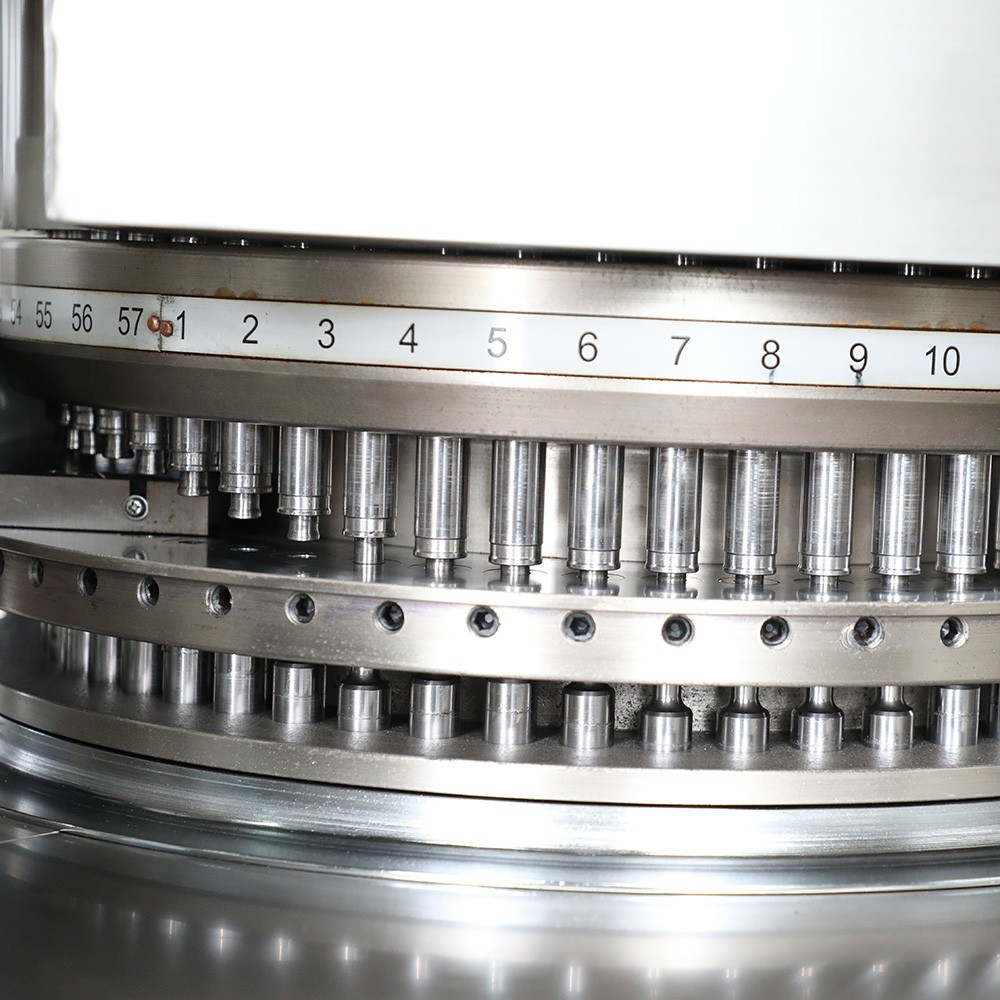

3. 9-hole turntable device for Rotary Tablet Press With 9 Punches

The turntable is a monolithic casting, and there are 9 vertically arranged die holes around the hole. The hole device 9 is punched, and the whole sleeve is placed on the fixed vertical shaft. The worm is driven during operation, and the whole turntable holds all the dies for clockwise rotation. .

4, the drive shaft of the Rotary Tablet Press With 9 Punches with clutch device

The drive shaft is horizontally mounted in the bearing bracket, with a worm in the middle, a test hand wheel at the front end, a conical disc clutch at the rear end, a handle control switch and a stop, and the clutch contact is transmitted by the pressure of the coil spring, if the load of the machine When the pressure of the spring is exceeded, the slip occurs so that the machine is not seriously damaged.

Rotary Tablet Press With 9 Punches Technique Parameter

Type | ZP-9A |

Dies | 9 |

Max.pressure(kn) | 40 |

Max.Dia.of Tablet(mm) | 12 |

Max.Depth of Fill(mm) | 15 |

Max.Thickness of Tablet(mm) | 6 |

Turret Speed(r/min) | 30 |

Production Capacity(pc/h) | 16200 |

Motor(kw) | 1.5 |

Overall Size(mm) | 400*580*1000 |

Net Weight(kg) | 310 |

Rotary Tablet Press With 9 Punches Main Application:

Rotary Tablet Press With 9 Punches is a new generation product by our factory, and this machine is a single Roller continuous automatic tablet press for pressing various kinds of different shape tablets and plain tablets It is mainly used in pharmaceutical industry and also the chemical, food, electronic industries.

Rotary Tablet Press With 9 Punches features:

The Rotary Tablet Press With 9 Punches features a high quality all stainless steel construction. High quality safety sealing system and dustproof system. Make the tablets more clean and hygienic

The Rotary Tablet Press With 9 Punches uses a high visibility isolation door to prevent cross contamination. Parts can be easily removed for quick maintenance of the machine.