- tj

- shanghai,china

- 15-30days

- 30 units per month

The Rotary Double Layers Tablet Press With Two Hoppers, as the name suggests, it has two hoppers, so the raw material is delivered faster, which is the biggest difference between it and other tablet presses.

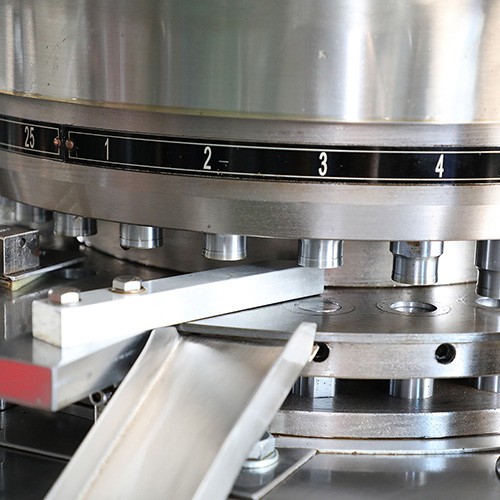

Rotary Double Layers Tablet Press With Two Hoopers

Rotary Double Layers Tablet Press With Two Hoopers working principle

In the production process of the Rotary Double Layers Tablet Press With Two Hoopers, the raw materials and auxiliary materials should be processed by pulverization and filtration, and only after sufficient pulverization can the subsequent mixing and other processes be processed.

Choosing a good quality Rotary Double Layers Tablet Press With Two Hoopers can not only obtain satisfactory product quality, but also improve the tableting efficiency and reduce the cost of tableting.

Due to the dynamic changes of the Rotary Double Layers Tablet Press With Two Hoopers during the tableting process, the inconsistency of many material properties, and the complex relationship between the two, coupled with the variety and specifications of the tablet press, the two-layer sheet pressure The choice of the tablet is very difficult. To implement a safe, economical, reliable and effective tableting program, we must fully consider the different performance and influencing factors of various tablet presses.

Rotary Double Layers Tablet Press With Two Hoopers Technique parameter

Type | ZP-33D | ZP-35D | ZP-37D | ZP-41D |

Dies (sets) | 33 | 35 | 37 | 41 |

Max. Pressure (kn) | 80 | 80 | 80 | 80 |

Max. dia. of tablet (mm) | 13 | 13 | 13 | 13 |

Max. Depth of fill (mm) | 15 | 15 | 15 | 15 |

Thickness of largest tablet (mm) | 6 | 6 | 6 | 6 |

Turret speed (r/min) | 14-37 | 14-37 | 14-37 | 14-37 |

Production capacity (pc/h) | 130000 | 150000 | 160000 | 170000 |

Motor (kw) | 4 | 4 | 4 | 4 |

Overall dimensions(mm) | 980*1240*1690 | 980*1240*1690 | 1230*950*1670 | 1230*950*1670 |

Net weight (kg) | 1700 | 1700 | 1700 | 1700 |

The Rotary Double Layers Tablet Press With Two Hoppers, as the name suggests, it has two hoppers, so the raw material is delivered faster, which is the biggest difference between it and other tablet presses.

The Rotary Double Layers Tablet Press With Two Hoppers is a device that can press a material such as a circular sheet, an engraving sheet, a shaped sheet, a double layer sheet, a multilayer sheet, a ring sheet, a package chip, etc., and is widely used in various fields. It is very important for a newcomer who has just mastered the two-layer tablet press. In the process of using raw materials and accessories, it is necessary to strictly abide by some problems.

In the working process of the Rotary Double Layers Tablet Press With Two Hoppers, the quality control of raw materials and auxiliary materials is very important and must be carried out according to the standard. Generally speaking, most of the auxiliary materials are polymer raw materials, so when selecting the model and specifications, it must be able to Match and guarantee no problems. At the same time, it is necessary to check and control the physical properties of the excipients. For example, the use of lubricants must consider the distribution of particle size and particle size.