- TJ

- shanghai,china

- 15-30days

- 30 units per month

TheHigh Pressure Fertilizer Tablet Press Machine is a small desktop electric continuous tableting machine. It can also be hand-cranked. The pressed tablets are uniform in thickness and high in gloss. No polishing is required.

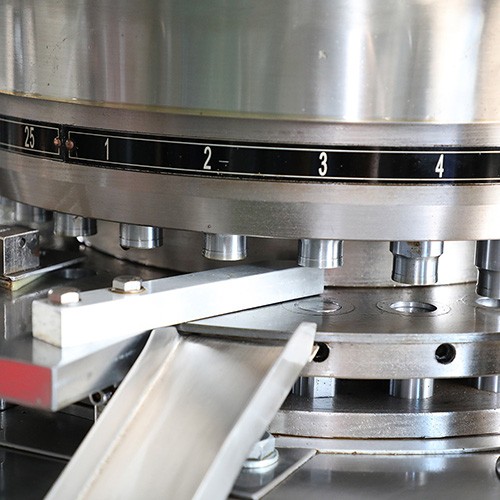

High Pressure Fertilizer Tablet Press Machine

High Pressure Fertilizer Tablet Press Machine feeding system

At present, most of the forced feeding systems of High Pressure Fertilizer Tablet Press Machine mainly include three parts:

(1) The hopper part of the High Pressure Fertilizer Tablet Press Machine mainly serves to store materials, and the lower part is connected with the forced feeder;

(2) The gear motor part of the High Pressure Fertilizer Tablet Press Machine is the power source of the forced feeding system, mainly including the three-phase/single-phase motor and the worm gear reducer. The output speed is adjustable by the inverter, and the lower part is connected with the forced feeder;

(3) The forced feeder of the High Pressure Fertilizer Tablet Press Machine, the main function is to fill the material into the various die holes on the turntable, and complete the final mission of the forced feeding system, so the forced feeder is the core component of the entire forced feeding system. The structure of the forced feeder is mainly to use the gear meshing to convert the one-way rotation of the geared motor into the reverse rotation of the two material impellers, and the material is filled from the material cavity into the die hole of the turntable by the material of the material.

High Pressure Fertilizer Tablet Press Machine Technique parameter

Model | HSZP-35 | HSZP-37 | HSZP-43 | HSZP-45 | HSZP-53 | HSZP-57 | |

No.of Stations | 35 | 37 | 43 | 45 | 53 | 57 | |

Type of Tooling | IPT | IPT | IPT | IPT | IPT | IPT | |

Max. Pressure (kn) | 80 | 80 | 80 | 80 | 80 | 80 | |

Max. Pre-pressure (kn) | 60 | 60 | 60 | 60 | 60 | 60 | |

Max. Filling Depth (mm) | 18 | 18 | 18 | 18 | 18 | 18 | |

Max. Tablet Dia (mm) | 25 | 23 | 18 | 17 | 13 | 11 | |

Max. Tablets output (ten thousand/ hour) | 18.9 | 19.98 | 23.22 | 24.3 | 28.62 | 30.78 | |

Max. Turret Speed (r/min) | 45 | 45 | 45 | 45 | 45 | 45 | |

Main Motor Power(kw) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | |

Height of the Machine (mm) | Without Hopper | 1750 | 1750 | 1750 | 1750 | 1750 | 1750 |

With Hopper | 1900 | 1900 | 1900 | 1900 | 1900 | 1900 | |

Machine Floor Space (mm²) | 1170*1290 | 1170*1290 | 1170*1290 | 1170*1290 | 1170*1290 | 1170*1290 | |

Machine Net Weight(kg) | 3500 | 3500 | 3500 | 3500 | 3500 | 3500 | |

Installation and wiring of the High Pressure Fertilizer Tablet Press Machine

1. TheHigh Pressure Fertilizer Tablet Press Machine is a small desktop electric continuous tableting machine. It can also be hand-cranked. The pressed tablets are uniform in thickness and high in gloss. No polishing is required.

2. TheHigh Pressure Fertilizer Tablet Press Machine is mounted on a solid wooden workbench (also mounted on a concrete platform) with three M12 anchor screws. The height from the work surface to the ground is about 600 mm (hand-operated, easy to operate). In order to facilitate the disassembly and repair, the position piece corresponding to the lower punching rod on the wooden workbench should also have a hole of about 35 mm in diameter.

3. Before the High Pressure Fertilizer Tablet Press Machine turns on the motor power, connect the motor to the ground wire to ensure safety. Remove the V-belt, turn on the motor power, and start the motor to see if the motor rotates in the correct direction (the direction of rotation of the motor shaft should be opposite to the direction of the arrow on the shield or handwheel). If the direction of rotation is wrong, connect the cable separately and then the V-belt.